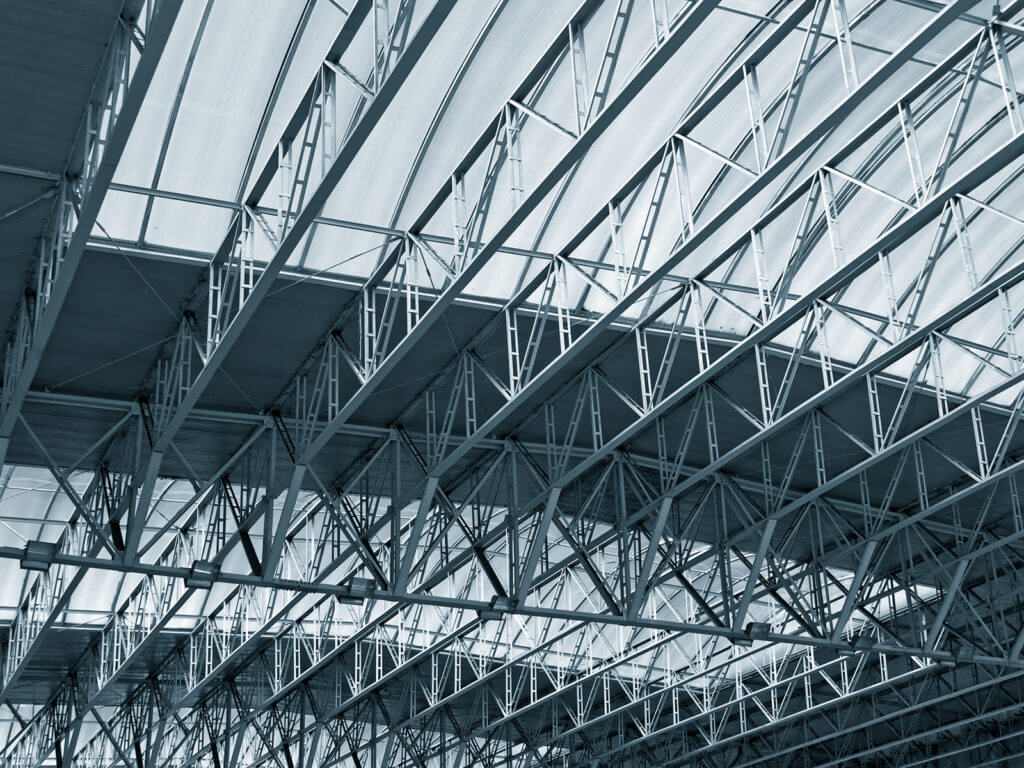

The construction industry stands as a testament to human engineering prowess, with towering skyscrapers, intricate bridges, and massive industrial structures that dominate our urban landscapes. However, beneath the surface of these architectural marvels lies a complex and crucial process that often goes unnoticed but is integral to their existence – steel detailing.

In this article, we delve into the world of steel detailing, with a special focus on the insights and expertise of Steel Detailing Jeemon VG, an authority in this field.

Understanding Steel Detailing

Steel detailing is the process of creating detailed plans and drawings for the fabrication and erection of steel structures. It is a crucial link in the chain of construction, acting as a bridge between the visionary designs of architects and structural engineers and the real-world steel structures that stand tall and sturdy.

At its core, steel detailing involves taking the structural engineering plans and transforming them into comprehensive drawings that provide steel fabricators and erectors with precise instructions. These drawings specify the dimensions, materials, connections, and other critical details necessary to bring the design to life. The process requires a deep understanding of engineering principles, construction techniques, and an acute eye for detail.

The Significance of Steel Detailing

Steel detailing may not be as glamorous as architectural design, but it is undoubtedly a critical component of the construction industry. Here are some key reasons why steel detailing is of utmost importance:

1. Ensures Structural Integrity

One of the primary responsibilities of steel detailers is to ensure the structural integrity of the final product. They must meticulously calculate loads, stresses, and forces to ensure that the steel structure can withstand the demands placed upon it. A minor error in detailing can lead to catastrophic consequences.

2. Cost Efficiency

Accurate steel detailing can significantly impact project costs. By providing precise measurements and material specifications, steel detailers help avoid wastage and reduce the need for costly modifications during construction. This efficiency translates into cost savings for builders and project owners.

3. Safety Compliance

Steel detailing is also crucial for ensuring compliance with safety regulations and building codes. Proper detailing ensures that a structure meets all safety standards, reducing the risk of accidents and injuries during construction and throughout the life of the building.

4. Streamlines Fabrication and Construction

Detailed steel drawings provide a roadmap for fabricators and erectors, streamlining the entire construction process. This leads to faster project completion times and reduced labor costs.

The Intricacies of Steel Detailing

Steel detailing is a highly specialized field that requires a unique set of skills and expertise. Here are some of the intricacies involved:

1. Precision Drawing

Steel detailers must create precise and detailed drawings that leave no room for interpretation. Even a minor error in a drawing can lead to significant issues during construction.

2. Material Selection

Choosing the right steel grades and materials is crucial for the structural integrity and longevity of a building. Detailers must consider factors such as load-bearing capacity, corrosion resistance, and cost-effectiveness when selecting materials.

3. Connection Design

The connections between steel members are critical points of consideration. Detailers must design connections that can withstand the forces and stresses that the structure will experience throughout its lifespan.

4. Coordination with Other Trades

Steel detailers must collaborate closely with architects, structural engineers, and other professionals involved in the project. Effective communication and coordination are essential to ensure that the steel structure aligns seamlessly with the overall building design.

The Evolution of Steel Detailing

The history of steel detailing is a story of technological advancement and adaptation. Over the years, this field has evolved significantly, thanks to innovations in both software and construction techniques. Jeemon VG, a distinguished figure in the realm of steel detailing, has witnessed and contributed to this evolution.

1. Manual Drafting to CAD

In the early days of steel detailing, drawings were created manually using pencils, pens, and drafting tools. This labor-intensive process was time-consuming and prone to errors. However, the advent of Computer-Aided Design (CAD) revolutionized the field. CAD software allowed detailers to create precise and easily modifiable drawings, enhancing accuracy and efficiency.

2. 3D Modeling

The introduction of 3D modeling technology marked another significant leap in steel detailing. 3D modeling allows detailers to create comprehensive digital representations of steel structures, providing a more holistic view of the project. This not only improves visualization but also aids in clash detection, where potential issues in design or construction can be identified and resolved before they become costly problems.

3. Building Information Modeling (BIM)

Building Information Modeling, or BIM, takes 3D modeling to the next level by incorporating data and information beyond just geometry. BIM software enables the creation of intelligent models that store detailed information about every aspect of a building, from materials and costs to maintenance schedules. This information can be invaluable for project management, facility maintenance, and decision-making throughout the building’s lifecycle.

4. Automation and AI

As technology continues to advance, automation and Artificial Intelligence (AI) are finding their way into steel detailing processes. These technologies can assist detailers in generating accurate drawings, optimizing material usage, and even performing structural analysis. Jeemon VG, as an expert in this field, has likely embraced and contributed to these technological advancements.

Jeemon VG: A Leading Authority in Steel Detailing

Jeemon VG’s name resonates strongly in the world of steel detailing. With years of experience and expertise, Jeemon has made significant contributions to the field, both as a practitioner and as an educator. His insights and knowledge have been instrumental in shaping the way steel detailing is perceived and practiced today.

1. Educational Contributions

Steel Detailing Jeemon VG has been an advocate for education and training in steel detailing. He understands the importance of nurturing the next generation of detailers who will carry the torch forward. His contributions to educational programs and training initiatives have helped raise the standards of the profession.

2. Industry Leadership

Jeemon’s leadership within the steel detailing community has been influential in fostering collaboration and knowledge-sharing. He has likely been involved in industry associations and organizations that work to advance the field and set best practices.

3. Technological Innovation

In a field where technology plays an increasingly crucial role, Steel Detailing Jeemon VGhas likely been at the forefront of embracing and driving technological innovations. His work may have involved the implementation of cutting-edge software and tools to enhance the efficiency and accuracy of steel detailing processes.

Conclusion

Steel detailing is an unsung hero of the construction industry, playing a vital role in turning architectural dreams into tangible steel structures. It ensures safety, efficiency, and cost-effectiveness in the construction process. With the evolution of technology and the contributions of experts like Steel Detailing Jeemon VG, steel detailing continues to evolve and thrive.

As we look to the future of construction, we can expect further advancements in steel detailing, driven by a commitment to precision, sustainability, and innovation. Steel Detailing Jeemon VG and others like him will continue to lead the way, ensuring that the bridges between design and reality are strong and resilient, just like the steel structures they help create.